Rumored Buzz on Screen Printing Custom T-shirts Abilene

Little Known Questions About Screen Printing Custom T-shirts Abilene.

Table of ContentsExamine This Report on Screen Printing Custom T-shirts AbileneSome Known Incorrect Statements About Screen Printing Custom T-shirts Abilene 7 Easy Facts About Screen Printing Custom T-shirts Abilene Shown3 Easy Facts About Screen Printing Custom T-shirts Abilene ExplainedFacts About Screen Printing Custom T-shirts Abilene UncoveredAll about Screen Printing Custom T-shirts Abilene

No blending needed, treatments exceptionally swiftly, expensive, ideal for detailed job. Combination of Diazo and SBQ, calls for mixing, general remedy time is much less than Diazo, rate is reduced than SBQ. The transparent acetate movie is positioned on the emulsion-coated mesh screen very carefully under a bright light which creates the emulsion to harden and develop.Exposing the screen for a specific time will solidify the exposed locations of the display, and the remaining unhardened solution, if any type of, will certainly be washed away to leave a clear imprint on the display. The display is after that dried out, and if there are any touch-ups called for, it will certainly be done by the printer to make the imprint as near the original layout as possible.

The material to be printed is placed flat on the printing board, and the screen on top of the product in the wanted position, ready to be published. In this action, the published layout will certainly revive. The display is lowered down to the printing board. The preferred colour ink is contributed to the top of the display.

The ink presses via the open locations of the pattern and transfers on the underlying silk, consequently publishing the layout on the product. The stencil will have served its function as soon as all the things are published. A special cleaning fluid is utilized to eliminate the emulsion to recycle the mesh for producing brand-new patterns.

The 6-Minute Rule for Screen Printing Custom T-shirts Abilene

There are six various kinds of screen printing processes. The most usual display printing technique is area colour display printing.

It is much simpler to use as contrasted to various other screen printing methods. It can be an exceptional option for printing on t-shirts, coats, and hoodies, as an example. In halftone printing, single colours in gradients are printed. The whole procedure makes use of a solitary colour of ink, and this colour obtains half-toned, causing a different shade when taken a look at from a range.

Furthermore, it is an affordable approach because just one colour of ink is utilized. Grayscale printing is an exceptional approach of publishing full-colour pictures as one colour grayscales or halftones. The print will look extra thorough if the halftone has more dots. It is not a black and white technique; rather, it draws out the CMY or RGB or colour ranges just yet in tones of grey.

Not known Factual Statements About Screen Printing Custom T-shirts Abilene

Duotone printing uses the combination of two halftones for publishing the very same photo with two colours. A black halftone is published with black ink, and after that a second halftone is published with colour ink.

It entails the four basic colours cyan, magenta, yellow and black. These four colours are combined to generate the called for colour tones. It can be done manually however ideally ought to be done instantly for ideal outcomes. The substitute printing procedure combines the four-colour printing process with area colour printing. Considering that this method is useful for both lighter and darker tones, it is flexible and preferred with individuals looking to generate photorealistic print detail.

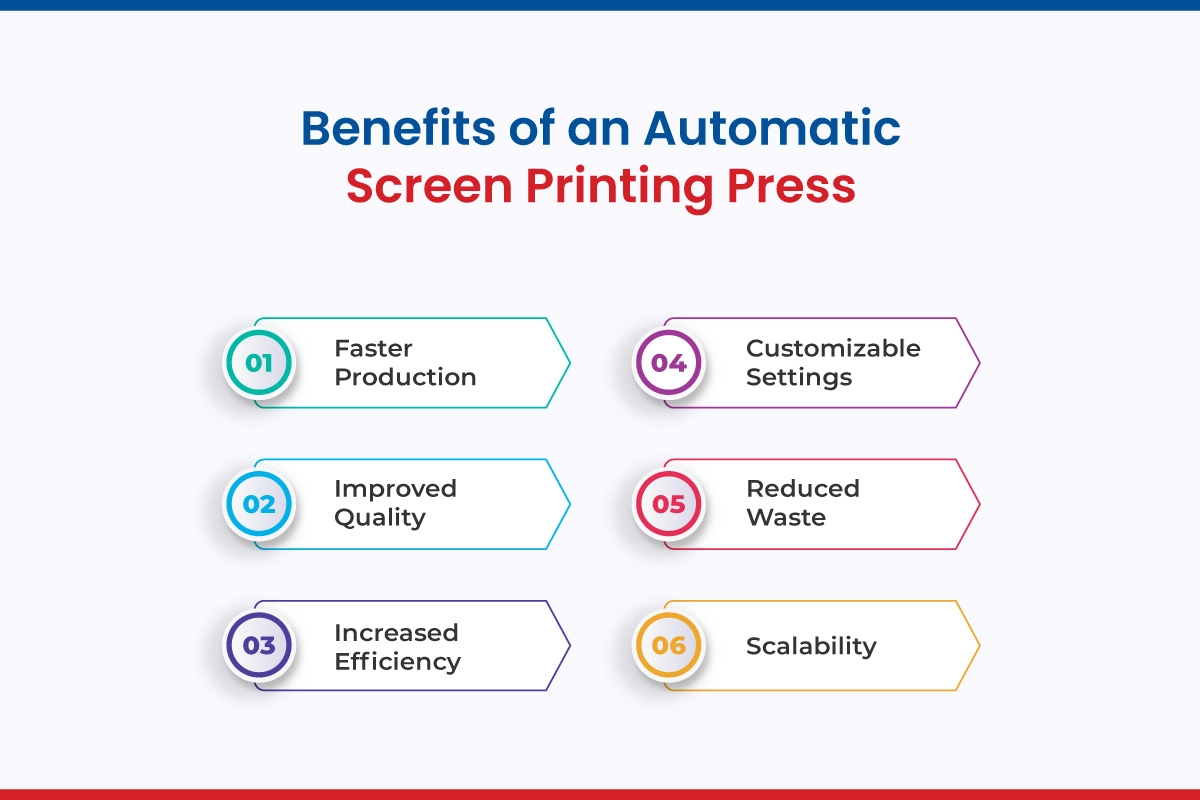

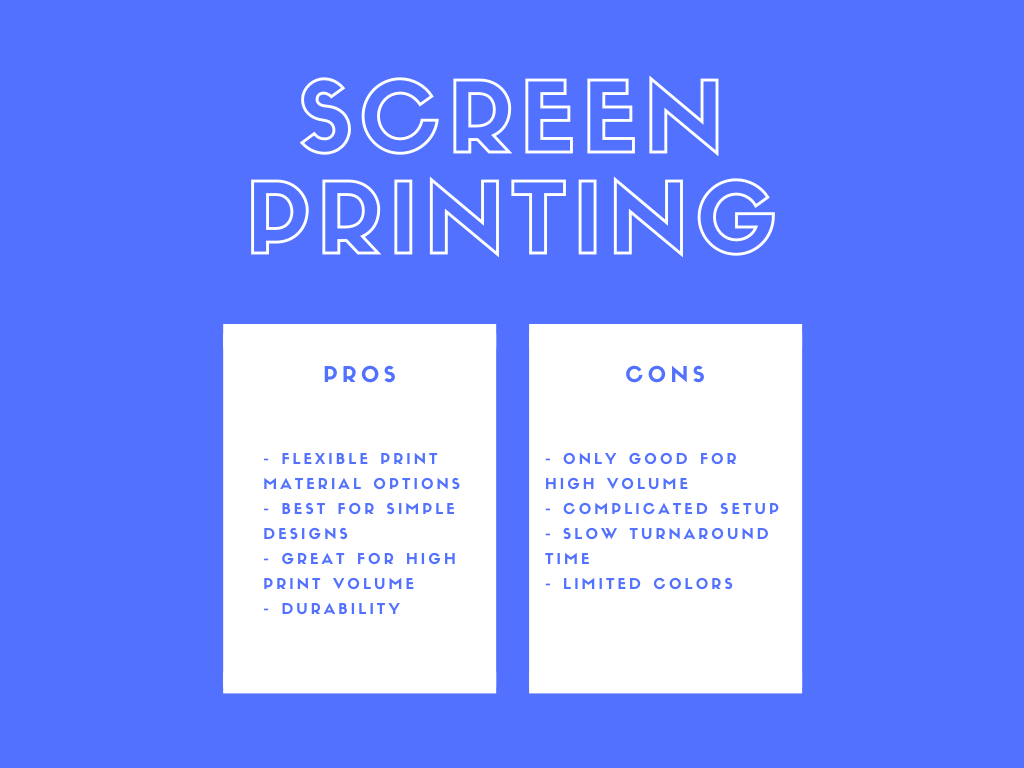

Some of these benefits include: One of the main benefits of screen printing is its adaptability. Compared to other printing techniques, screen printing can use a heavy ink protection, resulting in a sturdy style.

Screen Printing Custom T-shirts Abilene - The Facts

Screen printing is one of the most efficient and fast printing methods once a screen has been developed. The screen printing procedure is rather simple, whether it is automated or done manually.

Custom-made screen printing is a procedure that uses a mesh display to press ink in a predetermined style onto the textile of your selection. Screen printing is popular for customized tees, sweatshirts, coats, and a lot more. Custom-made screen printed tees or various other screen-printed garments are the ideal method for companies to increase their brand name presence.

Some Known Facts About Screen Printing Custom T-shirts Abilene.

The ink's durability ensures that prints stand up read more to repeated cleaning and put on, making it optimal for textiles like tee shirts, hoodies, and tote bags. This technique deals with a variety of surface areas, including textiles, plastics, glass, wood, and steels. Its flexibility allows organizations and developers to use designs to items like garments, advertising items, signs, and product packaging.

Advancements like computer-to-screen (CTS) and direct-to-screen (DTS) technologies are reinventing the screen printing procedure. These approaches eliminate the demand for standard movie positives by digitally transferring screen printing layouts directly onto the display.

The Definitive Guide for Screen Printing Custom T-shirts Abilene

While rooted in custom, display printing has actually embraced technical innovations to fulfill modern-day demands. Its mix of workmanship and innovation guarantees it remains a top selection for innovative and industrial printing projects. Screen printing remains to be a trusted and versatile printing method, providing lively shades and long lasting designs that stand out on a selection of materials.

Below are a few of them. Display printing can create a various visual outcome when compared to electronic printing. Screen printing ink is commonly used much more thickly, leading to longer-lasting, brighter and extra vivid colours, also on darker backgrounds. For garment design that calls for a high degree of vibrancy when printing on dark grounds, screen printing is still the very best option.

Thus higher volumes can be mass created utilizing screen printing much more quickly and even more expense effectively for bigger orders. Screen printing fits a large array of products, including plastic, fabric, rigid plastic, foam board, metal, glass and lots of others.